Is It Safe to Buy Used Pallet Rack?

Posted on Jun 9, 2022

Buying used industrial racking may be okay for straightforward use; but for complexity, longevity, expansion, or seismic issues, a new rack is best.

In the tough economy, many warehouse managers and owners are tempted to save a little by purchasing used industrial racking. While this can be a viable option, it can cost more than expected and have limitations down the line. So when does it make sense to buy an old vs. new pallet rack?

In general, buying used industrial storage racking might make sense when it’s in decent condition, relatively new, used in a non-seismic situation, and basically just uprights and beams (not a specialized system) where there’s no intermixing of competitors’ products.

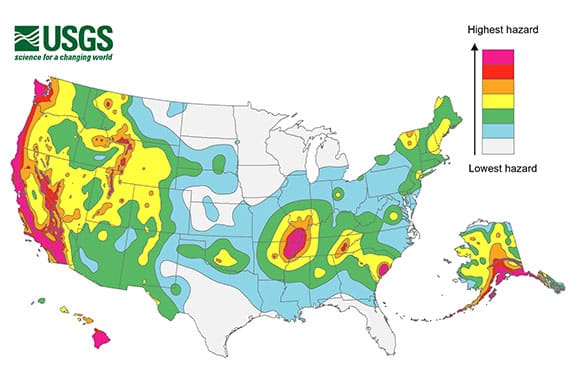

However, seismic map changes and stricter requirements make getting help more of a necessity today than in the past. “Only a few areas were designed to seismic requirements in the past,” says Steel King Engineer Arlin Keck. “Now the requirements are stricter and the zoning broader. If you buy a rack in one area, it may not pass code in another.” Steel King, a major designer and manufacturer of warehouse material handling, storage, and safety products, has been helping plan warehouses since 1970.

Changing building codes and certification requirements can also make buying used industrial racking a little more iffy. Changes in specifications mean that old capacity ratings may not meet current specifications. Thus, the rack might not be “permitable” at the old ratings.

The Rack Manufacturers Institute (RMI) publishes a racking design specification, and the American Iron and Steel Institute (AISI) and American Institute of Steel Construction (AISC) each publish a steel design specification. Your used industrial racking system must be in compliance with these specifications along with your local building and fire codes.

Current RMI certification, for instance, requires a load plaque stating the maximum rack capacity for fork truck drivers. Older warehouse racks not only lack such load plaques but also rack capacity documentation.

“As a rule of thumb, if you can’t easily find used storage rack capacity and documentation online, you should probably pass,” says Keck. “The same is true if the manufacturer is out of business, or the product line is discontinued.” Making sure the seller has proper product liability insurance is important; for an out-of-business manufacturer, this may be a problem.

“An advantage of buying a new pallet rack is that it usually includes help with seismic calculations and permitting,” adds Keck. “Without such help, someone buying a used rack may need to pay for testing and consulting fees, which could erode any initial savings.”

It usually makes sense to buy a new pallet rack when it’ll be used in a high seismic zone, for more complex or integrated systems, and when future add-ons or extensions are likely, according to Keck.

Used Pallet Rack Guide: Finding The Right Solution

Along these lines, new pallet racks can be custom fit to a warehouse’s size, capacity, and process, whereas older rack usually requires more compromises or “workarounds” to fit existing facilities. For these reasons, Keck recommends new racks for any specialty applications such as pick modules with floorings, integration with other products, and automated handling systems.

Newer warehouse racks also tend to have the advantage of being constructed from premium steel, with yield strength in the 50,000-psi range, as opposed to older commercial steel, typically in the 33,000-psi range. Since the newer premium steel is about 50 percent stronger, this translates into higher rack structures, greater capacity, and seismic resistance.

A new storage rack may have better quality control and beam fit, with closer tolerances and plumber racks. This aids material handling efficiency and reduces maintenance. The impact and chip resistance of newer racks’ powder-coated paint are also significantly better than older racks’ typical spray paint, which further reduces maintenance and enhances appearance. And while newer racks are almost assuredly specified with lead-free, non-toxic paint, older racks may not be.

What’s the verdict?

So when does it make sense to buy an old or new pallet rack? For the most straightforward applications, an older rack may be fine. But for anything where complexity, longevity, or expansion may be involved, a new rack may be the best choice. To do otherwise, may be “penny-wise and pound-foolish.”

Steel King is the nation’s only single-source manufacturer of pallet racks, pushback racks, drive-in racks, portable racks, cantilever racks, custom shipping racks, mezzanines, pick modules, industrial containers, and industrial safety guard railing. It is an active member of the Rack Manufacturers Institute (RMI), the Material Handling Industry (MHI), the Storage Manufacturers Association (SMA), the Reusable Container and Pallet Association (RCPA), and the Material Handling Equipment Distributors Association (MHEDA).