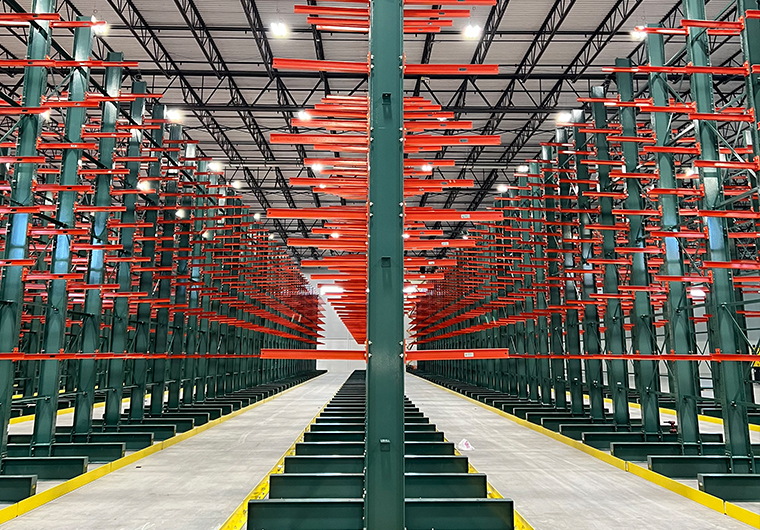

I-Beam Cantilever Rack

I-Beam Cantilever racks are unique among racks in that they employ vertical supports at the rear of the rack only, with “arms” extending from the columns at the back of the cantilever rack storage system to support loads. The benefit of this configuration is wide-open access at the front of the rack for loading and storing a wide variety of long, bulky, or awkward loads. The arms, which are available in a wide variety of styles and sizes, are easily reconfigured to make this an ideal solution for storing long and bulky items such as building materials utilizing a heavy-duty cantilever racking system to support the weight of the items.

Cantilever steel storage racks can be used indoors or outdoors. With the addition of decking, cantilever rack storage can also provide similar storage to pallet racking, with the advantage that, with no front column, there is easy access for loading and unloading as each storage slot is immediately accessible. This can lower your handling time and costs. The arms provide adjustable rack openings that easily accommodate various load dimensions.

Request a Quote for I-Beam Cantilever RackRequest A Quote ![]()

Store product on both sides with I-Beam Cantilever rack

I-Beam Cantilever storage racks allow access from both sides. This design saves horizontal space normally lost to rack structure, reduces fork truck damage, and allows for faster load and unload times.

Steel King’s cantilever rack is constructed of structural steel with a 50,000 psi minimum yield.

>With freestanding heights up to 30′ and 8′ arm lengths that can adjust vertically in 4″ increments.

With a heavy arm connector plate and bolted column-to-base connections, they’re a rugged addition to your storage lineup for storing:

- Steel bars

- Wood

- Plywood & Lumber

- Furniture

- Appliances

- Pipe

- Structural members

- Sheet steel

- Tubing

- Doors

- Boxes

- Pallets

- Conduit

- Extrusions

- Rolls

- Building materials

Available Colors

Steel King racking is painted with a high-durability powder coat paint finish.

Powder coated products offer better resistance to water and corrosion, better gloss, hardness, and adhesion. In fact, Steel King powder coated products give you:

- 60% Greater Resistance to Solvents

- 74% Greater Resistance to Salt Spray

- 94% Greater Impact Resistance

As a Steel King customer, this means that your equipment looks better, requires less maintenance, and lasts longer. Buying Steel King powder coated products is better for the environment too, because unlike liquid paints, powder coat paints do not emit fumes into the air.

Products come in 5 standard (see asterisks below) and 8 premium colors. Custom colors are also available.

More Steel King Products

Safety Products

Keep your people, products and facility safe with Steel King protective guarding, safety gates and products that protect racking from damage.

Containers

Industrial containers for durable, heavy-duty stackable storage, scrap handling, line assembly dispensary, parts distribution, and other uses.

Pallet Rack

Steel pallet rack engineered and built strong to withstand the daily wear, tear and abuse that can take a toll on your facility and your bottom line.

SOLUTIONS FOR EVERY INDUSTRY.

Request a Quote for I-Beam Cantilever RackRequest A Quote ![]()